|

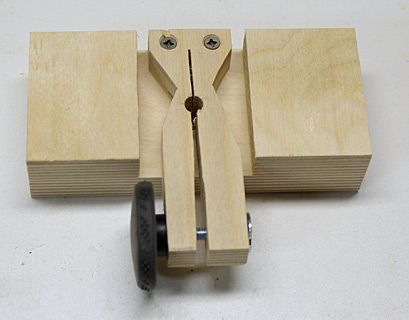

This should look familiar, but if you didn't make the height adjuster bracket back at the cabinet assembly now is the time. On my original version I used 5/16" threaded rod, and noted back then it wasn't ideal. What would be best is an acme threaded rod, but I can't find any acorn nuts with an acme thread, and didn't want to try grinding a curve or point on the rod. It works well enough with a regular thread once we go through some contortions. A larger diameter rod couldn't hurt, but 5/16ths is convenient. |

|

A t-nut alone is terrible for this application, way too much play. Under the t-nut goes two layers of 3/4" ply. The top layer is sort of a lock, but it doesn't really prevent you from being able to turn it, just to keep it from spinning on its own accord. I had no lock on my original version and over three years it only spun by itself a handful of times, but it's annoying when it happens. So this is more of a friction-adjuster than a lock. On the t-nut for the lock knob I bent all but one of the points flat in a vise so it wouldn't split the plywood. The bottom layer has another of the bushings that were used for the table pivot. This assembly gets screwed to the support plate. |

|

The full assembly. At the top of the rod is an acorn nut tightened against a nut, and the bottom wheel has a t-nut in it tightened against a nut. The acorn nut pushes against a fender washer, which is just loose between the nut and table. With the weight of the table it's not going anywhere. |